We have already had a rough understanding on how to identify driver’s performance difference from its label and appearance. And today we are going to share with you a new method to identify driver’s performance difference when we haven’t received the driver—parameters such as output, input, protection, application environment and so on.

1. Output parameters

From driver’s output parameters such as output current, output voltage and so on, we can confirm whether they match for the parameters of light fixture. Except for the mentioned parameters, we can also pay attention to the following ones:

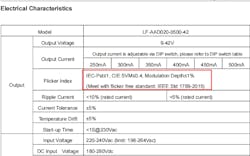

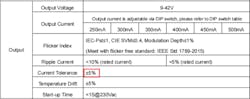

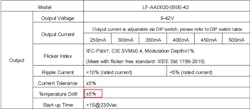

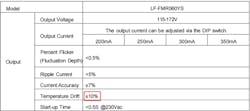

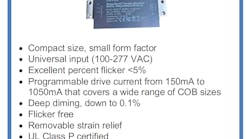

a. Flicker

As we all know, flicker does harm to our eyes, and its specific parameters can be expressed in a variety of ways, such as fluctuation depth, ripple current and so on. Among them, parameters such as Pst, SVM, fluctuation depth and so on are involved in the flicker index of Lifud LED driver based on the requirements of ErP and educational lighting, and we can tell if the driver meets the flicker-free standard according to the above parameters.

b. Current tolerance

It is the fluctuation value of driver’s output current, and the higher the accuracy is, the smaller the fluctuation will be, and the better the brightness consistency of all light fixtures in batch mode can be.

c. Temperature drift

The fluctuation of parameters is susceptible to the ambient temperature change, and if this fluctuation is excessive, the circuit of LED driver may fail to work. It is common when the fluctuation ranges from -15% to +15%, but the fluctuation of Lifud LED drivers’ parameters ranges between±5% and±10%.

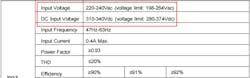

2. Input parameters

It consists of input voltage, input current, surge and other parameters. And different areas such as high voltage area, low voltage area, full voltage area (such as industrial electricity in the United States) and so on have different requirements on the voltage range. Generally speaking, wider voltage can be adapted to a wider area, but the corresponding cost is also higher.

Common voltage in different regions across the world (AC)

Note: the input voltage in the same country may be different due to different cities and regions.

The rated input voltage of Lifud LED drivers is available in a wide range of 220-240Vac, 100-277Vac and 120-347Vac, and the voltage limit ranges among 198-264Vac, 90-305Vac and 108-380Vac (different products have slight differences). In case of emergency, most of Lifud LED drivers can be used with DC input.

As for efficiency, PF and other parameters we mentioned last time, please check the previous text for more information.

3. Protection and application environment

These two parts mainly reflect the protection characteristics of an LED driver and the environment scope in which an LED driver can be applied. For example, the open circuit protection and short circuit protection that are specified in every Lifud LED driver’s specification are aimed at protecting the performance of LED driver when the driver works in the abnormal circuit.

When it comes to the application environment, please pay attention that the operating temperature not be too high because the driver may fail to work in the high temperature. As for the application environment of built-in track light LED driver, it is recommended that its operating temperature reach +50℃ and above. For example, Lifud high-end track light LED driver LF-GICxxxYS can work in the highest temperature of 60℃.

In order to ensure that all of Lifud LED drivers can work well as the descriptions in their specifications before shipment, they have to “suffer from” nearly 20 rigorous environment reliability tests, such as thermal shock test, high/low temperature storage & operation tests, “double 85” test, lifetime acceleration test, etc.

Lifud environment reliability laboratory

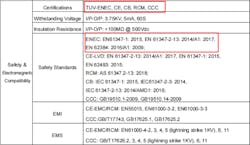

4. Safety and EMC

Last time we shared with you the main application areas and items of different certifications. Please check Lifud previous text for more details. And today we are going to further explain what certifications can different LED drivers’ performances meet and the corresponding standard numbers.

For example, this Lifud LED driver has been certified by TUV-ENEC, CCC, RCM, CE, CB, etc. And among these certifications, the standards of ENEC are EN61347-1:2015, EN 61347-2-13: 2014/A1:2017, EN 62384: 2016/A1: 2009.

Other parameters

This part mainly includes IP rating, RoHS standard, warranty condition, etc.

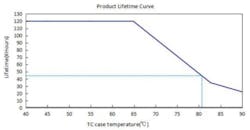

Among them, the warranty condition “5 years (Tc≤80.5℃)” means that the 5-year warranty service of this LED driver is valid on the condition that the casing temperature of the driver is not more than 80.5℃. For more information about the lifetime condition of an LED driver in different application temperature, please check the lifetime curve in the specification for reference.

Lifetime curve for reference

Basically, Lifud LED drivers are guaranteed for 5 years or more, and the 5-year lifetime is calculated on the condition that the LED driver continuously works 24/7 for 5 years. According to customers’ actual use, a Lifud LED driver with 5-year warranty may be used for up to 10 years.

As a globally recognized environment protection standard, the full name of RoHS Standard is “Directive on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment”. And basically all of Lifud LED drivers conform to RoHS 2.0 (EU) 2015/863.

The above parameters that can be easily understood are beneficial to identify the performance difference of an LED driver and they will help you to initially identify which product model is suitable for your project.

For more information about Lifud LED drivers, please contact us by +86 (0)755-83739299 or [email protected].